Latest news

Short videos and pictures Pedro shares with the community. Videos are unedited and their purpose is simply to share the progress of the building of these historic machines.

And Pedro asks us all to please excuse his dirty fingers!

Troubleshooting the phonograph: Recorder and reproducer

29thJanuary 2023

After some weeks off because a surgery I'm back working on the final steps of the Gillett. This time I', working on the reproducer. My tests revealed that it is extremely fiddly to set up the recorder and reproducer to work properly. Each time that the cylinder is shaved the set screws of the spectacle must be reset and the procedure requires several attempts that can take easily over an hour. And on top of that, either you know exactly what you are doing or you will end up with a damaged wax cylinder or a broken diaphragm.

So, I decided to come back to the original sources and read again the correspondence between the builders ad Gillett and see what solutions were proposed to the problem.

Several designs were discussed and all assess the main problem: the lack of vertical and lateral compliance of the reproducer and recorder that makes it very difficult to use. If you have used a tinfoIl phonograph, it is the same problem but instead of having only to perfectly set the height of the stylus, you need also to take care of the lateral position to ride exactly on the bottom of the groove..

In the next days, I will modify them and start again the final tests.

Troubleshooting the phonograph: Improved motor

25th September 2022

First of all, several readers asked me about Bottonne's books. Here are the links to them:

- The Dynamo: How Made and how Used

- Electro-motors: how Made and how Used: A Handbook for Amateurs and Practical Men

- Electrical Instrument Making for Amateurs: A Practical Handbook

They are worth a reading because he explains in easy words many electrical concepts that we never managed to learn at school.

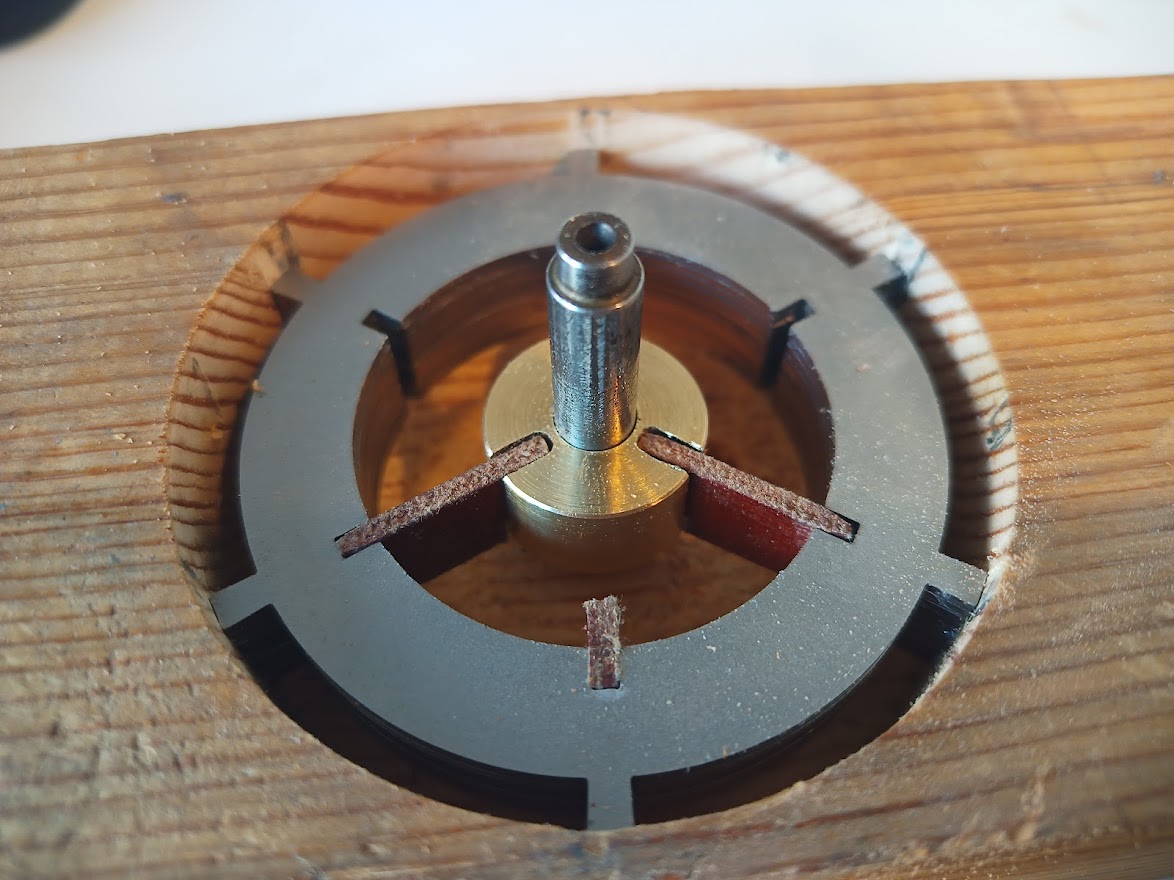

Following his suggestions, I modified accordingly the motor adding pegs to the rotor and designing a new collector and brushes.

I also redesigned the rotor spider to allow an easier winding of the rotor ("easier" means "take just under 9 hours to wind it"!) and made a wood jig to align everything

The result is very promising and I can't wait to install it on the phonograph.

Troubleshooting the phonograph: Motor

5th September 2022

Just before summer vacations I tested the phonograph and the motor is, as expected, noisy and barely powerful enough.

Why I was expecting it you may wonder. Well, the builders during 1892/1893 asked lots of questions in th The English Mechanic regarding the motor. The manly two machines that exist today from that era are the perfect example of the trouble that this motor gives. One was found without motor and the other one has a motor adapted from one made by Immisch & Co

So, What to do to improve its performance while maintaining a period correct motor? I found the answer in the books of Selimo Romeo Bottone, an electrical engineer that answered many questions regarding the motors to the builders and was also a prolific writer.

I grabbed 3 of his books and went on vacation hoping to find answers. And I found them! The books are very well written and can be understood by anyone.

So, after returning from vacation I designed the new pieces following Bottone's suggestions and very soon a new motor will be ready.

Watch the video for all the details,

Troubleshooting the phonograph: speed regulator

10th July 2022

Now that the machine is finished and before starting the final tests I have to address some issues that might make this machine unreliable.

I just cannot ship across the oceans to my customers an unreliable machine that is intended to hold its value and give them endless years of satisfaction. So far, I have detected 4 failure prone points that I will iterate until I correct them in this first unit and adopt the modifications in the next 9 units.

So far, these failure prone points are:

- Half nut: In the original blueprints it is threaded directly in the repeating lever bracket. If this thread gets damaged it will require major surgery so I opted to make a detachable half nut.

- Speed regulator: I address this problem in the attached video

- Brushes: They are noisy and its lifespan is about 4 hours. A much more robust and silent solution is needed.

- Spectacle spring & latch assembly.: I already solved it but I do not discard a new iteration to make a more elegant spring.

Repeating lever

3rd July 2022

I waited until I casted the wax cylinders and made the styluses to finish the repeating lever and drill the hole for the pin of Fig 13 that connects it to the column & spectacle because I needed to measure everything and place it in the exact correct position. If the pin is placed too high or low it doesn't work and the margin of error is less than 2 degrees.

I also changed the position of the shaver to correct Gillett's blueprint mistake.

Spectacle

26th June 2022

Just a short video of the 60+ pieces of the spectacle put together. As mentioned inthe video, I have installed glass diaphragms for the first test but I already have parchment, tracing paper, ferrotype and aluminium diaphragms to test them and choose the best combination.

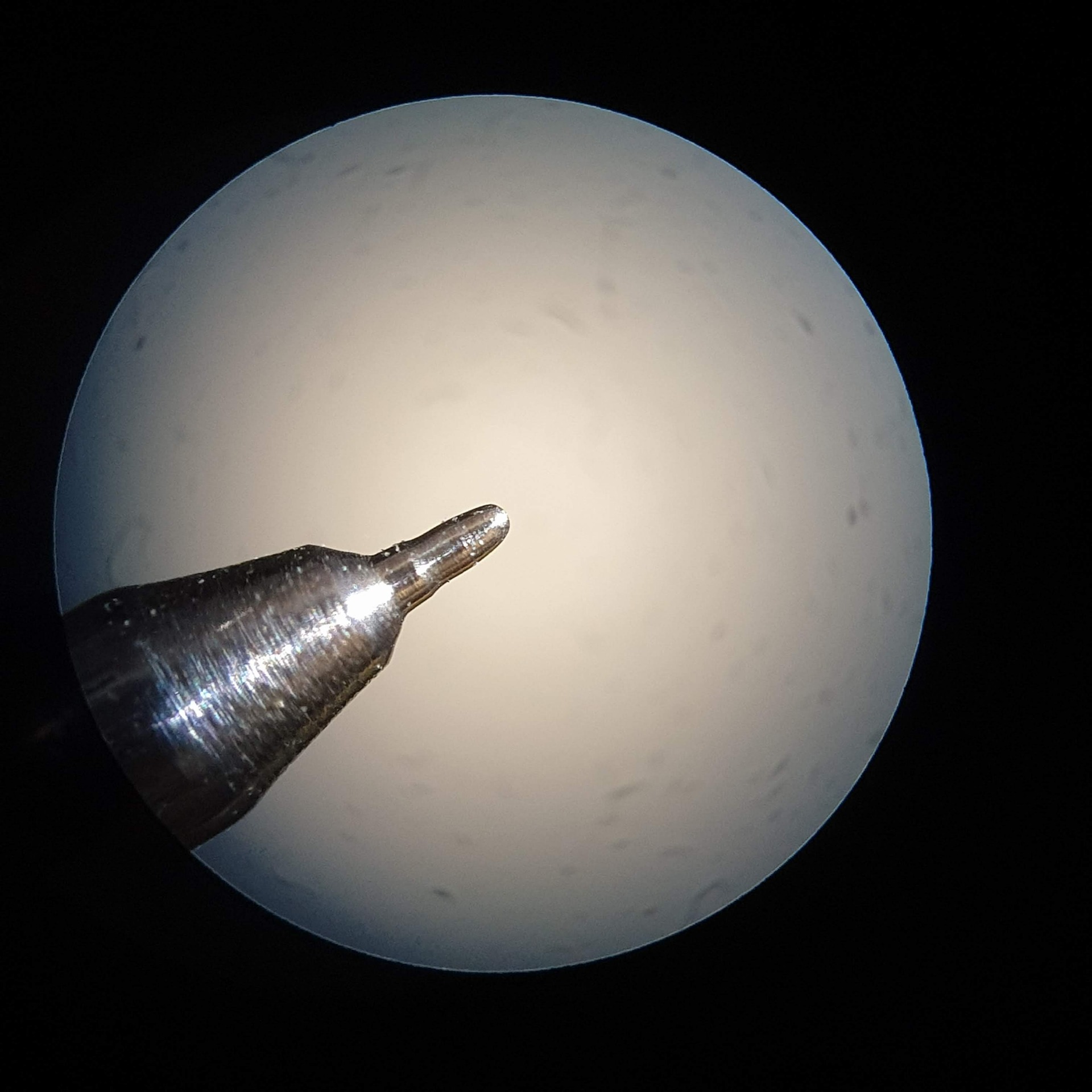

Reproducer and recording styluses

19th June 2022

Making these styluses proved to be far more challenging than expected. The size of them is extremely small if you compare them with Edison ones (1/100" diameter instead of 1/32").

I wonder why Gillett was pushing the limits to this extreme in many aspects of his phonograph. The leadscrew is also finer (130 tpi instead of the Edison 100 tpi) and the cylinder is almost twice the size of an Edison turns 3 times slower (50 to 60 rpm instead of Edison 160 rpm).

On the other hand, in my opinion, the design of the styluses is very basic and follows the same design as the ones used on tinfoils.

Many modifications were suggested by the builders to improve their performance so If they prove to be too basic I will study the possibility to modify them using one of the proposed alternatives.

Cylinder shaver problems

12th June 2022

Gillett's blueprints are riddled with errors. This is especially true with the column that supports the spectacle and all the related parts. I think that when he shortened it to correct the distance to the cylinder, he forgot to modify some of the dimensions of the position of the different parts that are attached to it.

It's time to solve this 131 years old error.

First successful wax cylinders

29th May 2022

This week I had several very interesting conversations with some chemists. I soon realized that using litharge (Lead Oxide II) was out of question because it is almost impossible to buy nowadays. If mixed with aluminium it reacts violently and it is highly toxic.

One thing kept turning in my mind. What could be those "white wax thin flat cakes" that gave a waste material that was a "kind of powder" that Gillett described on his book?. None of the waxes I have bought makes powder when it is scratched.

None of them? Well, in my box of ingredients ONE thing was a powder. The stearic acid of one of the bags is a powder! The stearic acid is in fact a saturated fatty acid so it can be melt like a wax. It is used in small proportions (3 to 10%) in some candles to give them more strength. What if the wax described by Gillett is nothing more than a paraffin wax with a high content in stearic acid?

A call to one of my chemist friends confirmed that I might be in the right direction and suggested me to try a 30% stearic acid and 70% high quality paraffin.

So I tried it and you can see the result in the video.

We are progressing in the right direction. I managed to cast a perfect cylinder that was very easy to take out from the mould and looks like it has the correct stiffness.

Wax cylinders

22nd May 2022

William Gillett is very vague sometimes while describing his phonograph. Regarding the wax to be used to cast the cylinders, he just says: "The best I have found for this purpose is white wax (...), is sold at most oil shops in the form of thin flat cakes. Its price is about three shillings per pound."

So, I grabbed 3 shillings, put them in my pocket and went to the nearest oil shop and... (just kidding)

It was time to start investigating what could be that white wax and I made a discovery that will be documented in my book. Until then, if you want to know my findings watch the video!

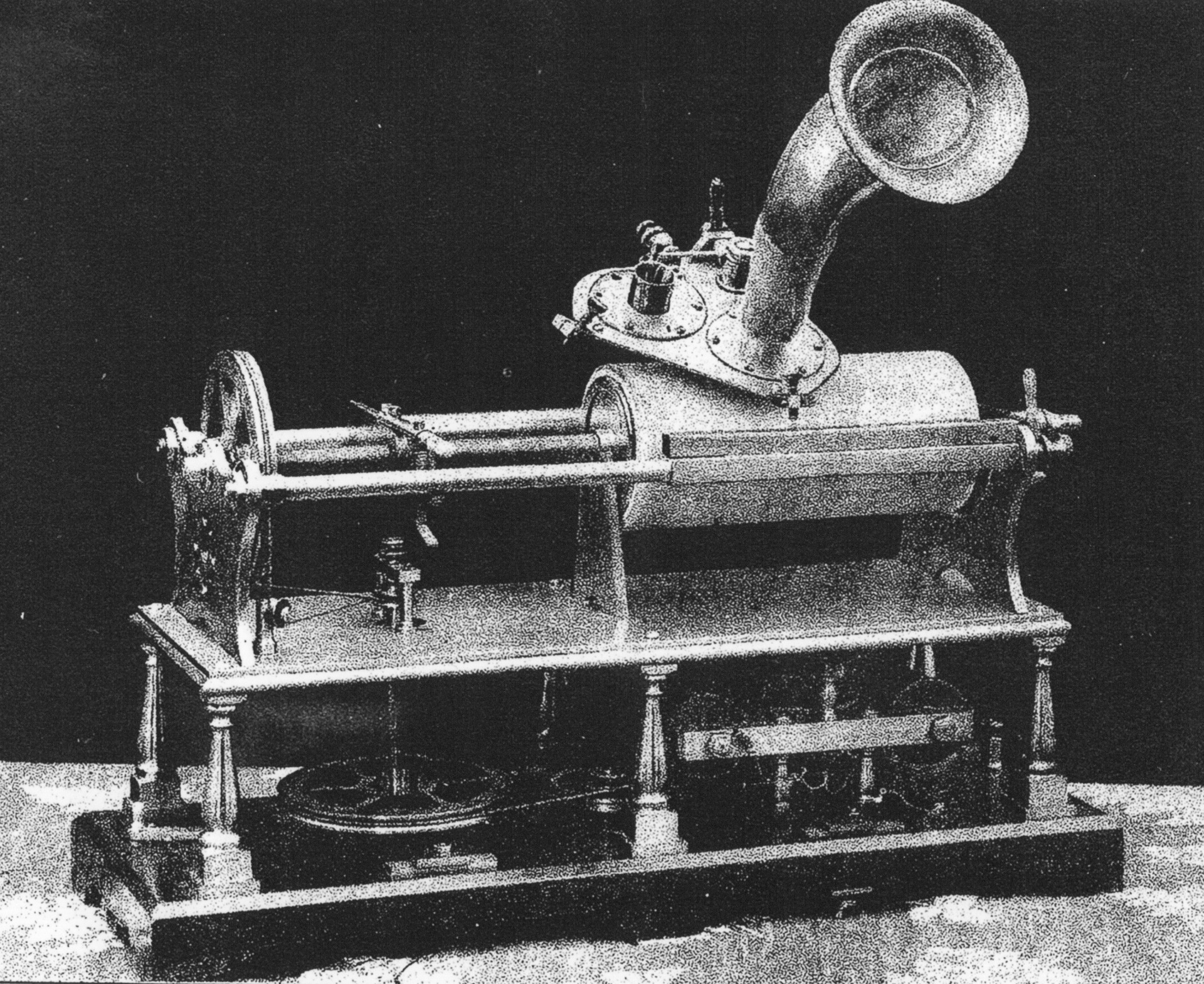

The iconic curved horn

22nd April 2022

One of the most prominent features of the Gillett Phonograph is the very peculiar curved horn. To my amazement, Gillett did not include it on the blueprints not in the description until you read the penultimate paragraph of the book.

He says: "It will also be observed that instead of an ordinary cone, I have fitted a horn to the phonograph; this horn having a brass flange round the mouth. The horn adds very much to the instruments appearance."

I think that Gillett saw Bettinni's phonograph picture published on The English Mechanic when he started writing his articles and wanted to imitate it.

So it was time to put to work my humble brass instruments build skills and make one.

Pretty close, isn't it?

Speed regulator installed

5th April 2022

Gillett managed to design a speed regulator to be installed in the available space. That is why it doesn't have a an attaching point in the top side and ended making such a complex design.

On the second picture you can see the very clever design of the switch. When the wights make the springs expand, the brushes go downwards until the one you see on the right loses contact with its ring thus cutting off the current. Meanwhile, the left one is still in contact with the bottom ring so it doesn't fell out of it.

By turning the upper knurled nut, you can fine tune the speed by adding the load of the central spring to the ones that have the weights.

Speed regulator

2nd April 2022

I cannot figure out if this is genius or just over-engineering. In Gillett's original book, there was no provision for speed regulation, apart from varying the current going to the motor. So, around 1894, just months before his death, Gillett published an article showing how to build a speed regulator.

Rather than the simple "yoke-and-felt-pad" construction of most centrifugal governors, Gillett designed an incredibly complicated unit that is both mechanical and electrical. And it was difficult to build!

More and more, I understand why only one contemporary machine has survived! Watch the video, please.

Toggle-joint spring

27th March 2022

Another Gillett design flaw has been exposed. If one follows the original working drawings, well, it won't work. Gillett even says so in his book and the one existing phonograph made according to his design (which is the frontispiece to his book) has a very different construction. It is interesting that he didn't change his blueprints before publication.

Diaphragm covers

26th March 2022

It is frustrating that Gillett's drawings are not always consistent. I ended up drilling some holes that I needed to plug again. But Eric, who bought the very first machine, understands that this is basically a prototype for the other nine machines and has no objections.

Honestly, I think I will be the first person in the world to make more than one Gillett! Keep posted. We are getting near the end!

Pulleys

24th March 2022

Time to get everything lined up so that the power of the motor is transferred to the feed screw. And I need to source proper belting material, not the silicone I am using to mock things up. But it is all gradually coming together and I am SO pleased with the result!

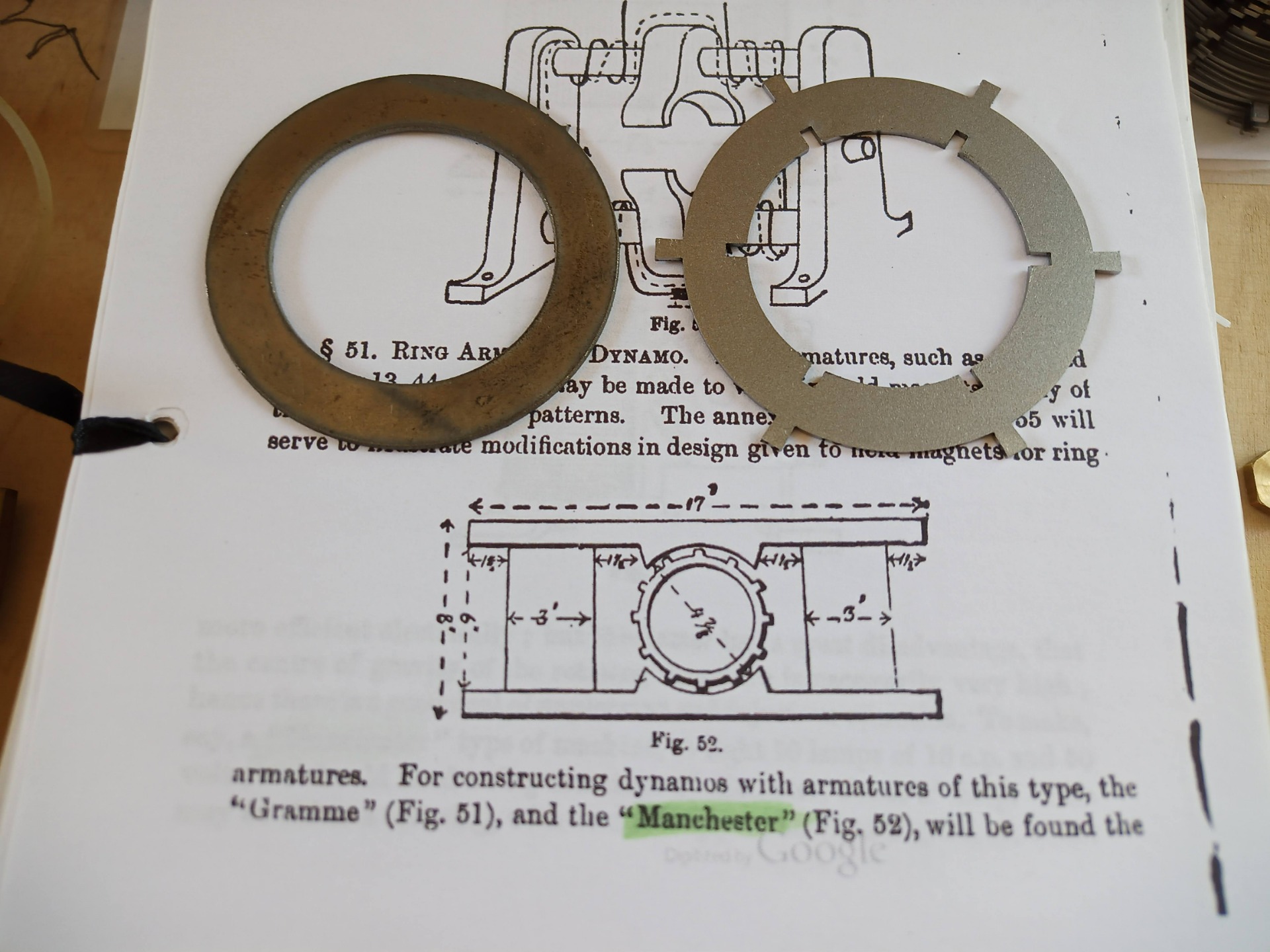

Electro-motor assembly and maintenance

18th March 2022

Over a third of the hundreds of parts in the Gillett are used to make the Manchester-style motor. This has been a real challenge to build - and I better understand why the only surviving Gillett from the 1890s has a motor borrowed from some other device, perhaps an electric fan.

But I think you will enjoy seeing how all of this goes together. Very complicated. Very delicate. Very interesting! Now I just have nine others to build :)

Electro motor completed

11th March 2022

This has been such fun! It has been a huge task and some collectors have told me that Gillett's motor would never work. Well, I proved them wrong. I still have some balancing work to do to reduce noise, but I am very, very happy with the result.

The difficulty of making this motor was already mentioned back in 1891 by the first builders.

Electro-motor commutator

12 March 2022

The commutator is finally finished. What a job this has been, but very satisfying. Now I just need to get the rest of the machine ready for the unveiling at the Rüdesheim, DE fair in early April. I have less than a month and a LOT more work to do.

Spectacle machining

1st March 2022

I made a stupid mistake and forgot to machine the indentation for the diaphragm in the spectacle mount. That meant I needed to actually machine new tools so that I could finish the job properly. I think I may have to invest in a bigger lathe at some point - but as they say, "necessity is the mother of invention."

Electro-motor rotor coils

7th december 2021

This is a crazy project! There are six coils, each containing 16 meters of wire, 180 turns. So, 1080 turns in total. It took me THREE attempts to get it right. But it will work when I am done.

For those of you who question the EUR 10K price of a finished machine, you really don't want to know how much copper and brass costs these days. And I hope you appreciate how much work goes into building each machine.

Electro-motor rotor

7th December 2021

Having built the rotor, now it needs to be wrapped in paraffin-soaked strips before winding the coils. Melting paraffin at home is a dangerous process, as you can see in the video! But I am taking every precaution.

Rudesheim Fair

6 November 2021

And the work-in-progress Gillett arrives in Rüdesheim for the first unveiling!

Mahogany base and repeating lever

1 November 2021

I really enjoyed building the mahogany base. It is made from solid mahogany sourced from an old piano. Happily, I have enough for all 10 machines.

The real challenge now is the mandrel. And I haven't yet come up with a good solution. The problem is that solid brass rods are simply not available in the needed diameter for the Gillett-style mandrel I am building here. So, I made it out of steel, which unfortunately rusts. I am not quite sure how to finish it so that humidity - and even fingerprints - ruin the surface. And soon, I will have to figure out how to make some cylinders that conform to the Gillett drawings, which are not the same as the Edison cylinders, probably for legal reasons.

Columns and sliding tubes

31st October 2021

Wow. As if making the very fine feedscrew, which has a much smaller diameter than those on, for example, and Edison Class M, making the sliding tube that guides the recorder/reproducer "spectacle" along the support rods was a real challenge.

There are no fewer than SIX precision bushings in this assembly. And anyone who has ever taken apart an Edison "Standard" will appreciate the brilliant simplicity of Edison's design. On the other hand, I suspect this is the point at which a lot of home machinists back in the 1890s gave up on the project.

Although, I have tried to remain 100% honest to Gillett's drawings, I am going to make a removable half nut. Quite simply, if the half nut is damaged, the entire sliding tube would need major surgery if I followed Gillett's design. I like to think my machines will survive and function for at least 100 years without major issues.

Main shaft and mandrel

23rd October 2021

This was another tricky part of the construction as everything has to be perfectly aligned and balanced, and with minimal friction. But the final result was fantastic! The machine is really starting to take shape.

Cast-columns mould

10th October 2021

The Gillett needs six columns to attach the upper works to the base. I started by turning a wooden "master" on the lathe and then sand casting the brass columns. As this was very time consumiing, the video is on fast forward so you can follow the process.

Unfortunately, despite my best efforts, the finish was simply not up to my standards. Thus, I decided to make them on the lathe and solder on the square bits at each end. This is also very time consuming but produces a much nicer column. Stay tuned!

Gate-bearing center

3rd October 2021

Another hard day of work, this time to fabricate that rather complicated, spring-loaded mandrel bearing that is attached to the gate I made yesterday.

Gate

2nd October 2021

The end gate is finally in place! The drawings were slightly misleading and I had to make a second end gate as the center hole for the mandrel needed to be slightly off centre.

Guide rods

1st October 2021

Well, after almost a year of study, sourcing period-correct materials, and some initial fabrication of the upper-carriage frame, it was time to start building the guide rods for the recorder/reproducer mount.

As usual, there were a remarkable number of challenges even though one would think simple polished rods would not be much of a problem to make.

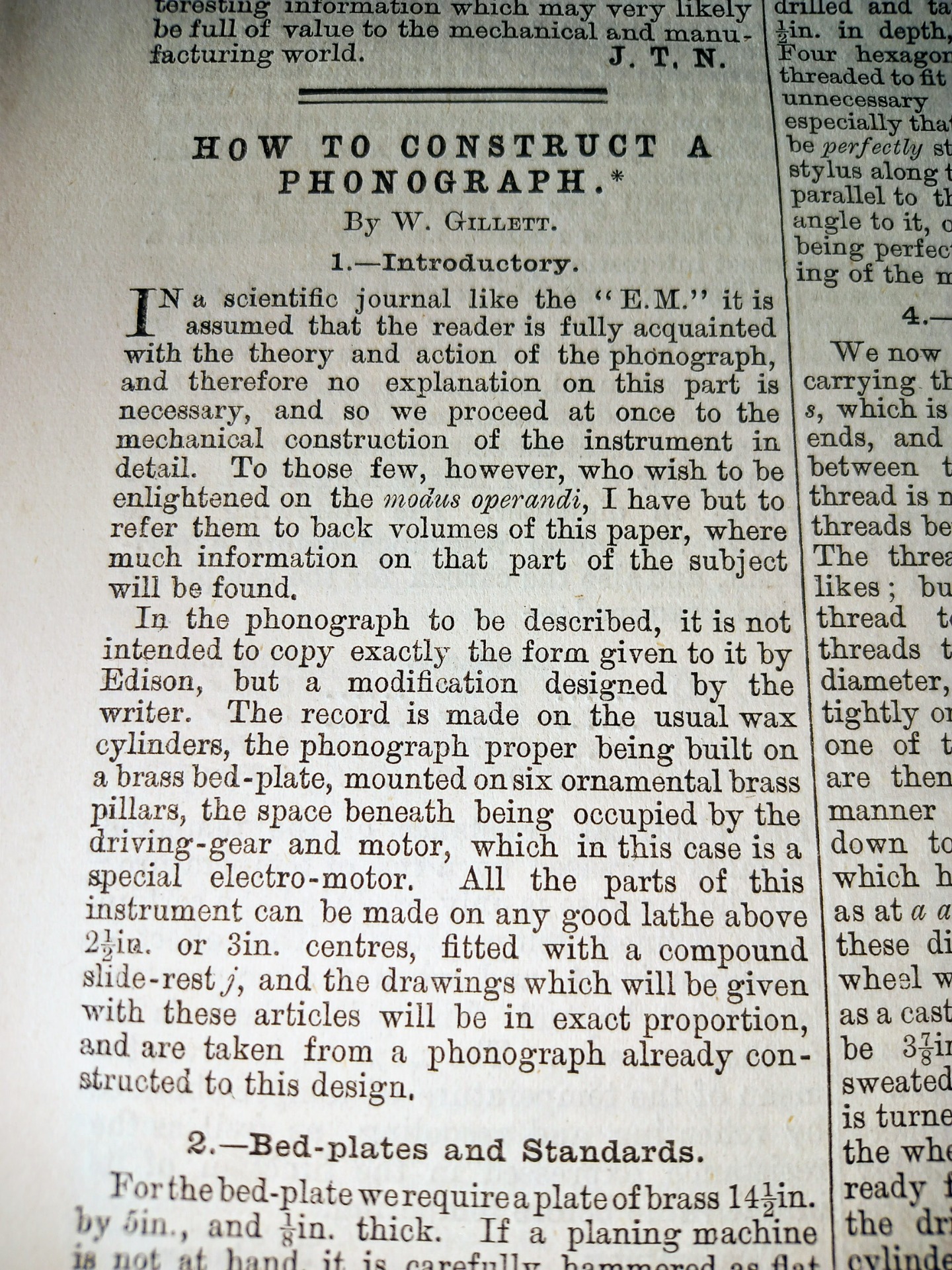

Arrival of the original articles and the research starts

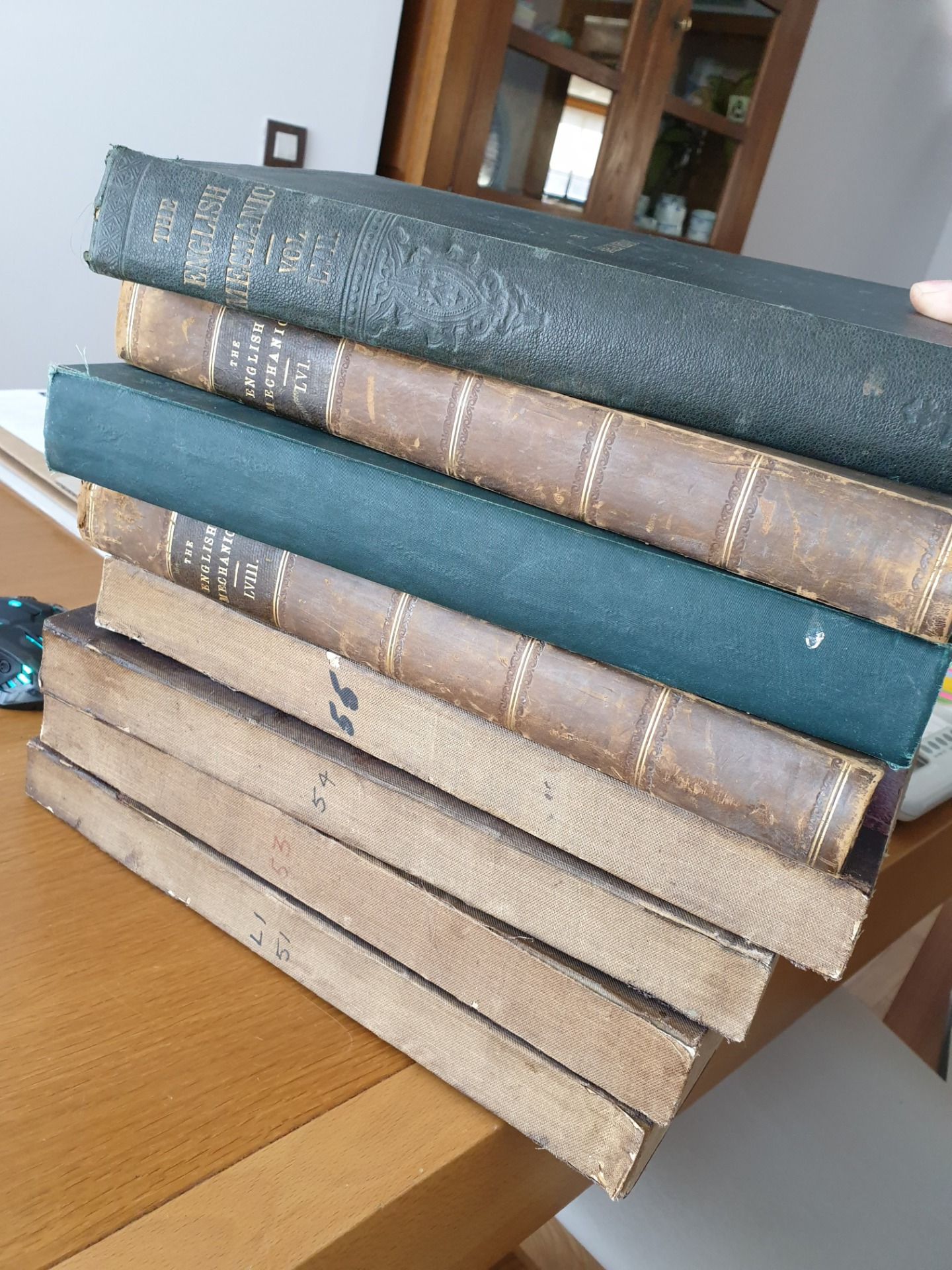

28th October 2020

The original copies of the English Mechanic and World of Science arrived! I was overwhelmed with the amount of information they have. Apart from the original articles written by William Gillett and all the questions of the builders and answers from Gillett, I found many other enthusiasts talking about phonographs - particularly Bettini and Edison machines - and endless fascinating inventions.

I called my father - and 20 minutes later I was at his home, asking him if he could help me with the enormous task of going through all the volumes, and extracting and consolidating all the information. He was immediately engaged in the project.

Just look at all the bookmarks! Each one of them represents either a question to Mr. Gillett or his answer. Thanks, Dad! This has been an enormous help!

The beginning

September/October 2020

My good friend, Eric Reiss in Denmark, just sent me a fascinating book. It was originally published in 1892 and describes how to make an electric phonograph, similar to the Edison Class M that was gaining favour at the time.

I first learned of this machine in a 2018 issue of The Antique Phonograph and have always been curious. And with the COVID lockdown, this is exactly the kind of project I have been looking for!

With some searching, I was also able to locate original copies of the English magazine, The English Mechanic and World of Science. Here, Gillette published a series of articles designed to improve his original concept and answered many questions from potential builders of this device. And my wonderful father, Victor Martínez, who understands some of the electrical issues better than I do, is helping push me in the right direction. Gracias, Papá!

And so, the adventure begins. It will be quite a journey! Hey, Eric, I'M IN! Tak, min ven!